The Fuel Audit: Why "Identical" Trucks Have Different Bottom Lines?

Prefer listening? Press play below to hear the AI-generated podcast version of this article.

In the world of logistics, there is a common, expensive mystery: two identical trucks, purchased in the same year, driving the same route from Baku to Tbilisi, yet one consistently burns 15% to 20% more fuel than the other.

When you ask why, the "Excuse Cycle" begins. Without high-fidelity data, leadership is often forced to accept these explanations as the unavoidable cost of doing business:

- The "Mechanical Ghost": "That engine is just tired; the injectors are probably clogged. You can't expect an older truck to perform like a brand-new one."

- The "Weight & Route" Defense: "I had a much heavier load this time," or "The road conditions through the mountain passes were terrible, forced me to stay in low gear for hours."

- The "Traffic Trap": "I was stuck at the border for 6 hours; I had to leave the engine running just to keep the cabin warm so I didn't freeze."

- The "Technical Glitch": "The sensors are wrong. Every time I hit a pothole or climb a steep grade, the fuel gauge jumps. It’s just 'noise' in the system."

To move beyond these excuses, we must move from "monitoring" to a Digital Audit Standard.

1. The Science of the "Gap"

Research confirms that the "Excuse Cycle" is often a mask for a widening gap between laboratory expectations and road reality.

A 2024 report by the European Commission found that real-world fuel consumption for diesel vehicles is 18% to 24% higher than official values. Furthermore, the International Council on Clean Transportation (ICCT) has documented that this "gap" has more than doubled in the last decade.

When a fleet manager relies on standard norms, they are using a measurement system that international authorities have already proven is insufficient for operational control.

2. The Three Truths: Choosing Your Data Source

To truly manage fuel, you must decide which "truth" you want to see. Each data source provides a different level of visibility, and understanding their technical strengths is the first step toward a professional audit.

A. The "Accounting" Truth (Math & Norms)

This method relies on mathematical models based on odometer readings and engine hours. A professional GPS tracking solution adds intelligence by applying Seasonal Coefficients (calculating the extra load from winter heaters and thickened lubricants) and Urban Cycle Logic (adjusting for stop-and-go traffic).

- The Limit: It is an estimation, not an observation. Because it is a virtual calculation, it is completely blind to theft. "Math" cannot see 30 liters siphoned from a stationary truck; it only knows how many kilometers were driven.

B. The "Engine’s" Truth (CAN Bus / Consumption Data)

By tapping into the vehicle’s digital heartbeat, we access the Total Fuel Used data directly from the Engine Control Unit (ECU). The engine’s computer calculates this value with extreme precision by monitoring the exact volume of fuel processed by the injectors.

- The Advantage: This is the gold standard for Accurate Consumption Tracking. Because the data is calculated by the engine itself, it provides a highly reliable record of how much fuel was actually combusted. This allows you to audit the "health" of your fleet—identifying if an engine is underperforming due to mechanical wear or if a vehicle is being operated inefficiently (such as aggressive torque demand or driving in the wrong gear).

- The Blind Spot: It misses "Return Line" theft. The ECU only tracks what enters the combustion chamber. If fuel is siphoned from the return line before it reaches the injectors, the CAN bus will report normal, "healthy" consumption even while your fuel is physically disappearing from the system.

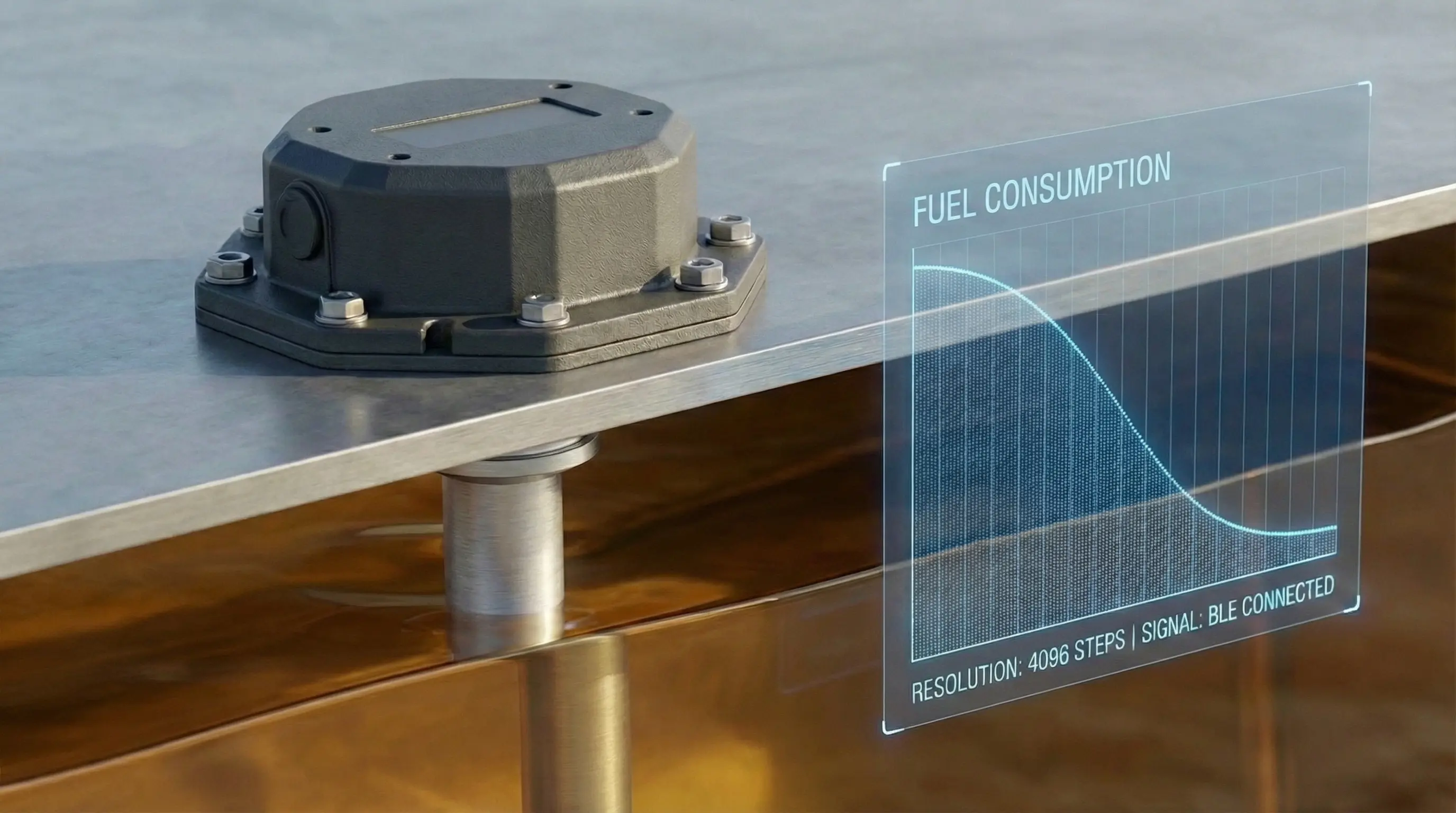

C. The "Physical" Truth (FLS – Fuel Level Sensors)

This method utilizes high-precision Wireless BLE (Bluetooth Low Energy) capacitive probes that provide 12-bit resolution, dividing the measured height of your tank into 4,096 discrete steps.

- Honest Accuracy & Blind Spots: No sensor is perfect. While a 12-bit FLS is far more precise than a factory float, it still has physical limits. Because the sensor must be installed securely with a mounting flange at the top and a small "safety gap" at the bottom (to prevent the probe from vibrating against the tank floor), it cannot measure the absolute 0% or 100% of the volume. Typically, the top and bottom 1–2% of the tank remain "blind." However, while a factory float might ignore 40+ liters at the top, a professional FLS narrows that window significantly.

- The Error Margin: In laboratory conditions, manufacturers claim a <1% error. In the real world, factors like fuel temperature expansion, tank deformation, and vibration mean a realistic 1–2% statistical discrepancy is normal. The goal of a professional audit isn't "perfect physics"—it's a consistent, high-resolution record that makes theft mathematically obvious.

- Why Internal Gauges Fail: Factory dashboard sensors (floats) are designed for driver comfort, not forensic auditing. They have massive "blind spots" (often 10% or more) because the mechanical float becomes fully submerged before the tank is even truly full. Furthermore, dashboard signals are electronically "smoothed" to hide sloshing, which often accidentally masks rapid, professional theft events.

- The Critical Step: Accuracy is only as good as the installation. Achieving millimeter-level precision requires a meticulous, step-by-step calibration (tank taring) performed by certified professionals. This involves filling the tank liter-by-liter to create a "digital twin" of the tank's unique geometry, ensuring the software interprets the sensor's signal as actual volume.

- The Reality: Despite its physical limits, this is the only irrefutable proof of security. It is the only method capable of detecting "drainage" events when the engine is off or the vehicle is parked overnight, providing the forensic evidence needed for a corporate investigation.

3. Solving the Human Variable: The Psychological Shift

In many fleets, the biggest obstacle to efficiency isn't the machine; it’s the "Driver Rotation Gap." When three different drivers operate the same truck over a single week, individual accountability vanishes. If a fuel spike occurs, it is impossible to pin down who was responsible, leading to a culture where "the truck is just thirsty" becomes the default excuse.

By integrating Driver Authentication (RFID cards or iButton keys), we move the focus from the vehicle to the individual.

- The "Right Foot" Accountability: The system creates a permanent digital link between a specific driver and the fuel consumed during their shift. Whether they are driving a brand-new Scania or an older KAMAZ, their "Driver Signature" follows them.

- The Behavioral Mirror: The psychological impact of transparency is immediate. When a driver knows that every instance of harsh braking, aggressive acceleration, and unnecessary idling is being recorded and ranked against their name, their driving style shifts from "aggressive" to "professional." The data acts as an undeniable mirror of their performance.

The results are backed by objective data. Research by the Fraunhofer Institute (ISI) demonstrates that this level of transparency and behavioral monitoring typically leads to a 5% to 15% reduction in total fuel consumption. It turns fuel management into a performance-based culture where the best drivers are recognized and the "right foot" problem is permanently solved.

4. The Analyst's Toolkit: Eliminating the "Noise"

Fuel is a liquid—it sloshes, expands with heat, and compresses with cold. On the rugged roads of the Caucasus, a basic monitoring system will send you dozens of "False Theft Alerts" that are actually just potholes or steep mountain inclines. True expert-level monitoring relies on a three-layer Validation Logic to ensure your alerts are actionable, not annoying.

Layer 1: Adaptive Median Filtering

Raw sensor data is "noisy." Without processing, a fuel graph looks like a serrated blade. We apply Adaptive Median Filtering—mathematical algorithms that analyze a window of data points to identify and remove "outliers" (sudden spikes caused by sloshing). This creates a smoothed, high-fidelity line that represents the actual fuel level, not the movement of the truck.

Layer 2: Multi-Sensor Logic Validation

We don't look at fuel in a vacuum. To confirm a "Drain" event, the system cross-references multiple data streams simultaneously. For a theft alert to be triggered, the following conditions must be met:

- Velocity = 0: The vehicle must be stationary.

- Ignition = Off: The engine is not drawing fuel.

- Time Threshold: The drop must occur over a specific duration that exceeds a normal consumption rate. Only when these logical "gates" are passed does the system move from a "fluctuation" to a "validated theft."

Layer 3: Forensic Data Analysis

Even the best algorithms can be fooled by a faulty sensor wire or a short circuit. This is where the human expert comes in. When a complex anomaly appears, our analysts dive into the Raw Data Messages (Hexadecimal logs). By looking at the raw voltage and sensor frequency, an experienced analyst can tell the difference between a real physical fuel loss and a technical "phantom drop" caused by an electrical interference.

Conclusion: The 360° Fuel Audit

Fuel monitoring is not simply about buying hardware; it’s about automating your internal controls. To achieve a truly comprehensive "Full Picture," a single data source is rarely enough. The most successful fleet managers implement a multi-layered hybrid approach:

- The Physical Layer (FLS): Provides the high-resolution security needed to detect drainage, overnight theft, and siphoning with millimeter precision.

- The Technical Layer (CAN Bus): Provides the truth about engine health, actual combustion, and mechanical efficiency.

- The Human Layer (Driver ID): Uses RFID or iButton authentication to close the accountability gap, ensuring every liter consumed is linked to a specific individual.

- The Analytical Layer: Professional validation logic and expert support to filter out "noise" and provide actionable business intelligence.

By combining these solutions, you turn a "guess" into a 360-degree, verified financial record. You move from wondering why costs are high to knowing exactly how to lower them.

If you are looking to implement a professional fuel audit standard or need help investigating anomalies in your fleet data, the certified team at A+A Security is here to provide the technical expertise and forensic support required to secure your assets.

Stay Connected! 🛰️ Follow A+A Security for the latest insights in fleet management and GPS technology. Your support helps us grow!